The packing problem is equal to the cutting problem, and the problem can also be called as an assortment problem. formed a mathematical model for packing a set of given rectangular items into a rectangular space in which the dimension of the rectangular space is minimized. Only a few studies attempted to develop deterministic approaches for an optimal solution. Moreover, the distance between one random feasible solution and the actual global optimal solution can be enlarged with an increasing problem size. ĭespite the development of heuristic approaches can obtain possible solution in a reasonable time, however there is a scarcity of literature attempting to ensure the achievement of an optimal solution. They applied geometric analytical techniques and Dantzig-Wolfe decomposition to produce various lower bounds of the 2DCSP so that a better solution can be compared and obtained. Likewise, Monaci and Toth initially used Lagrangian-based heuristic to generate a set of covering programming model to obtain a lower bound solution, in which the items cannot be rotated.

2d cutting optimizer update#

In order to enhance the effectiveness of the algorithm used, Boschetti and Mingozzi consider empty bins in turn and fill the bins with items in a sequence defined by the prices attributed to the items and update them iteratively. proposed an integrated heuristic approach that initiates the solution by paralleling the edges of the items and bins (i.e., materials) and utilizes a Tabu search to explore the neighborhood and refine the possible solution. Berkey and Wang proposed a finite best strip heuristic algorithm to improve the original bottom-left method which packs the items directly into the bins with a best-fit policy. Chazelle first proposed a popular heuristic algorithm, called the bottom-left heuristic algorithm. The feasible solution is obtained within a reasonable time, while the optimal solution cannot be guaranteed. The primary advantage of this approach is easier in solving the 2DCSP within an acceptable and economical timeframe. Various heuristic approaches have been proposed and discussed in the literatures. , Hopper and Turton, Lin and Martello et al.

) and suggested two categories of approaches in solving the problems, namely, the heuristic and deterministic approaches (Belov, Burke et al. The problem in the literatures have been classified as one-dimensional, 1.5-dimensional, and 2DCSPs (Hinxman and Lodi et al. Minimizing the number of materials is normally the target in this type of the problem because it does not only reduce the overhead consumption but also enhances environmental protection. These applications include sawing plates from wood stocks, reel and sheet cutting at a paper mill, cutting plates of thin-film-transistor liquid-crystal display (TFT-LCD) from glass substrate, placing devices into a system-on-a-chip circuit, and container loading or calculation of containers.

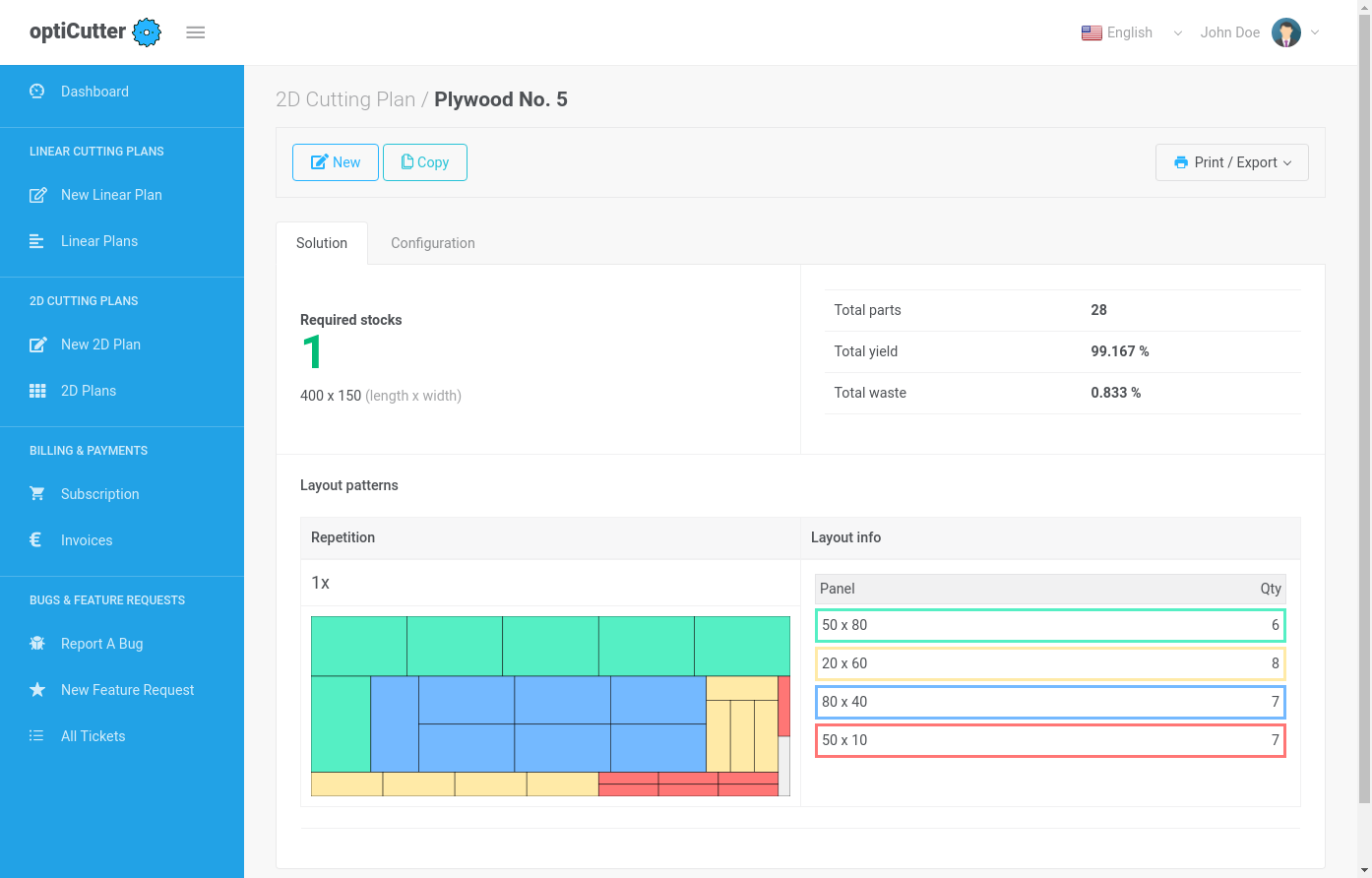

In the 2DCSP, a set of given rectangular items is cut from a set of rectangular materials with the aim of determining the minimum number of materials. The problem frequently arises in the manufacturing processes of different products such as wood, glass, paper, steel, etc. Two-dimensional cutting stock problem (2DCSP) is a well-known problem in the fields of management science and operations research.

0 kommentar(er)

0 kommentar(er)